Searching for information about concrete foam jacking? If so, don’t hit that back button because this article will answer your questions. We’re going to talk about what concrete foam jacking is, how it differs from mudjacking, why concrete foam jacking is better than mudjacking, and more.

Why Do Concrete Slabs Become Uneven?

Concrete slabs can become uneven due to erosion under the slab, which causes the soil to move around. Voids form, and then the slab sinks into them and becomes uneven.

Concrete slabs can also become uneven due to invasive tree roots pushing up on the slab from below. We’ve probably all seen examples of this, especially on sidewalks.

Slabs can also become uneven due to simple wear and tear. As pedestrians and vehicles use the slab, it gets compressed into the ground and eventually becomes unlevel.

What Is Concrete Foam Jacking?

Concrete foam jacking is a repair method for lifting and leveling uneven concrete slabs such as driveways, sidewalks, pool decks, patios, garage floors, warehouse floors, highways, etc. Foam jacking is a newer method for releveling uneven concrete that uses a synthetic material to relevel the slab. An older method called “mudjacking” uses a cement slurry to lift and level the slab. While mudjacking is still being used today by some contractors, foam jacking is more popular.

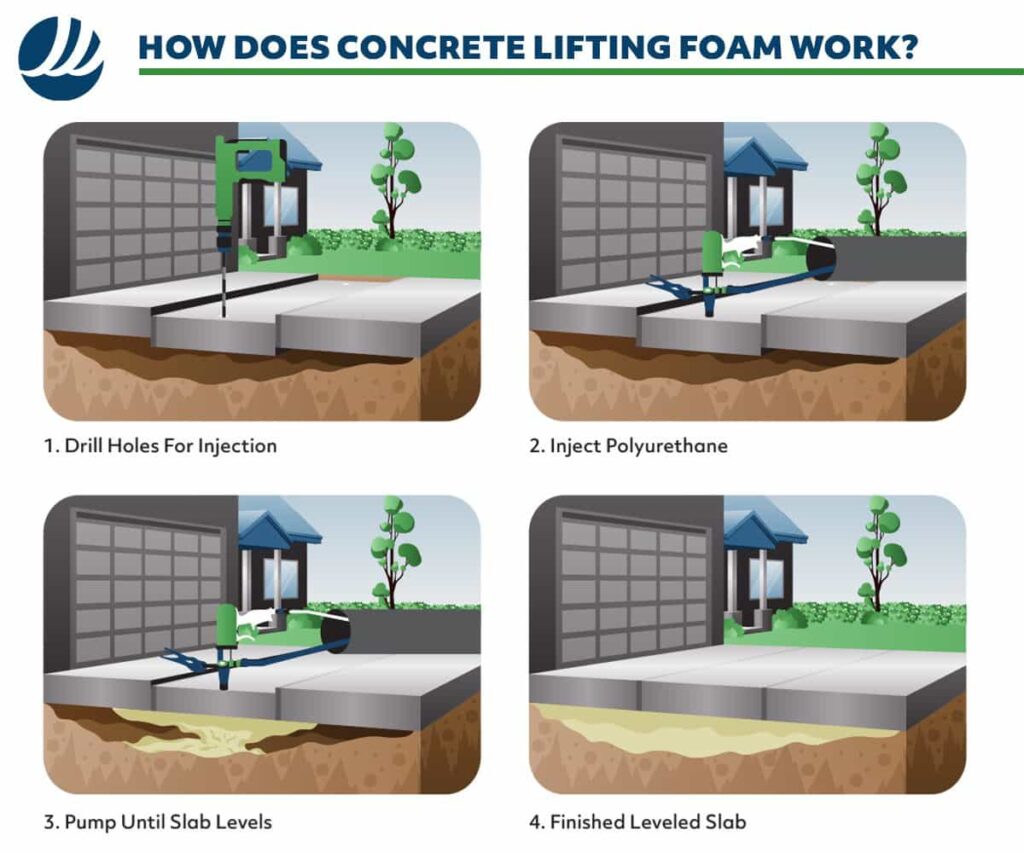

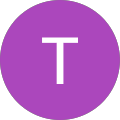

The foam jacking procedure involves…

- Drilling small, dime-sized holes in the uneven slab.

- Polyurethane foam is injected under the concrete via the holes.

- The foam immediately begins to expand, which lifts and levels the slab.

- The holes are patched using a compound that matches the concrete.

- 15 minutes after the repair is complete, the slab is ready for use again.

What’s The Difference Between Foam Jacking and Mudjacking?

Both mudjacking and foam jacking are techniques used to lift and relevel uneven concrete slabs like sidewalks, driveways, patios, and pool decks. Mudjacking, the older method, uses a slurry containing cement, sand, and other material. In contrast, concrete foam jacking uses a rapidly expanding synthetic foam to lift and level the slab. The foam fills the voids under the slab and compresses the soil.

The foam used in foam jacking is lightweight and adds only negligible weight to the soil. In contrast, the cement slurry used in mudjacking is heavy and adds considerable weight to the soil. In some cases, mudjacking can cause the slab to sink deeper into the soil. If that happens, you’ll need another repair.

The holes used in mudjacking to inject the cement slurry under the slab are roughly the size of a quarter. The holes used in foam jacking are dime-sized. However, when the repair is complete, both are patched using a compound that matches the color of the concrete.

Foam jacking is more expensive than mudjacking. However, it’s a faster repair that lasts longer because it uses a synthetic material that won’t erode to lift the slab. Therefore, you’ll be able to go longer without needing another repair.

For more information see, The Best Repair Methods for Sunken Concrete.

Why Foam Jacking Is Better Than Mudjacking?

While mudjacking is less expensive, that doesn’t mean it’s better or the preferred solution. In our opinion, concrete foam jacking is better than mudjacking for the following reasons:

- It lasts longer than mudjacking – The cement slurry used in mudjacking contains things like sand and soil. That makes it subject to erosion. If that happens, it will mean another repair. The material used in concrete foam jacking is synthetic and, because of this, won’t erode. Fewer repairs mean money saved.

- It’s a quick repair – Most concrete foam jacking jobs can be completed in just a few hours, and 15 minutes after the repair is complete, you can start using the slab again. With mudjacking, you could have 24 hours of downtime before the releveled slab is ready for use.

- The holes used in concrete foam jacking are smaller – This makes concrete foam jacking a less visible repair.

Why Do Some Say Mudjacking is Better Than Foam Jacking?

Some contractors argue that the foam used in foam jacking expands too rapidly underneath the slab and doesn’t fill all the voids. However, the temperature of the foam can be controlled. When the temperature is lowered, the foam spreads slowly and fills all the voids.

You’ll also hear some argue that the foam used in foam jacking is toxic. While it’s true that one element of the foam is slightly toxic by itself, when it’s mixed with the other element, it’s rendered harmless. The foam that comes out of the nozzle is already mixed and safe for both humans and animals.

Finally, there’s the argument that mudjacking is a longer-lasting solution. This isn’t true. As we mentioned above, the slurry used in mudjacking is subject to erosion. The synthetic foam used in concrete foam jacking isn’t.

How Much Does Foam Jacking Cost?

Concrete foam jacking costs more than mudjacking. However, it costs less than digging up and replacing the concrete – about 40% less, to be exact. So, it’s a significant saving over pouring a new slab.

Of course, the cost of concrete foam jacking will depend on where you live and the size of the area that needs lifting. The more foam used, the higher the price.

The only way to know how much it will cost to fix any uneven slab is to contact a foundation repair contractor near you that does concrete leveling and ask for an inspection and repair estimate.

If you have an uneven concrete slab and are in our service area in Kansas City, MO, contact KC Waterproofing and foundation repair today, and we’ll come out for an inspection and estimate.