Looking for information about raising a concrete slab with foam? If so, you’ve landed on the right page. While digging up and replacing an unlevel concrete slab is expensive and time-consuming, raising a concrete slab with foam only takes a few hours. As soon as the repair is complete, the slab is ready for use again.

This article will go over why concrete slabs become unlevel, how raising a concrete slab with foam works, why we believe raising a slab with foam is better than mudjacking, and more.

Why Do Concrete Slabs Become Unlevel?

Concrete slabs usually become uneven when the soil shifts underneath the slab. This creates movement under the slab causing it to eventually become uneven. The soil can shift for various reasons, including:

- Erosion – Soil prone to erosion can wash away, leaving voids behind. If the slab settles into the voids, it will become unlevel.

- Expansive soil – Expansive soil swells when it soaks up moisture and then shrinks when it dries out. This creates movement under the concrete and will, over time, lead to an uneven slab.

- Poor drainage – Expansive soil under the slab, along with poor drainage, can lead to the build-up of hydrostatic pressure under the slab. As the pressure pushes up against the slab, it could become unlevel.

- Soil that wasn’t adequately compacted before the slab was poured – Soil needs to be correctly tamped down before concrete is poured on top of it. If it isn’t, the slab will settle into the soil and become uneven. It could even crack.

- Tree roots looking for moisture – Tree roots get thirsty and will seek out water. If they start “drinking” water from the soil under the slab, the soil will dry out, forming voids into which the slab will sink.

- Invasive tree roots – We’ve all seen examples of tree roots pushing up on a slab. Tree roots can do a lot of damage to a slab. Sometimes, the slab will need to be torn up and replaced.

Traditionally, uneven concrete slabs were lifted and leveled using a technique called mudjacking. While mudjacking is still being used today, it’s not as popular as it once was. Today, raising a concrete slab with foam is more popular. Both repair methods involve drilling holes in the concrete and injecting material under it to raise the slab. Concrete leveling works on various slabs, including sidewalks, driveways, patios, pool decks, roads, and more.

Mudjacking(the traditional technique used for raising a concrete slab)

Mudjacking involves using a slurry containing cement, soil, sand, and other materials to lift an uneven concrete slab. The slurry looks like mud, and that’s why the procedure is called “mudjacking.”

- Step one: 2-3 inch holes are drilled into the slab that’s going to be raised.

- Step two: The cement slurry is injected under the slab to lift it.

- Step three: The holes are patched using a compound that matches the slab’s color

Approximately 24 hours after the repair is complete, the slab will be ready for use again.

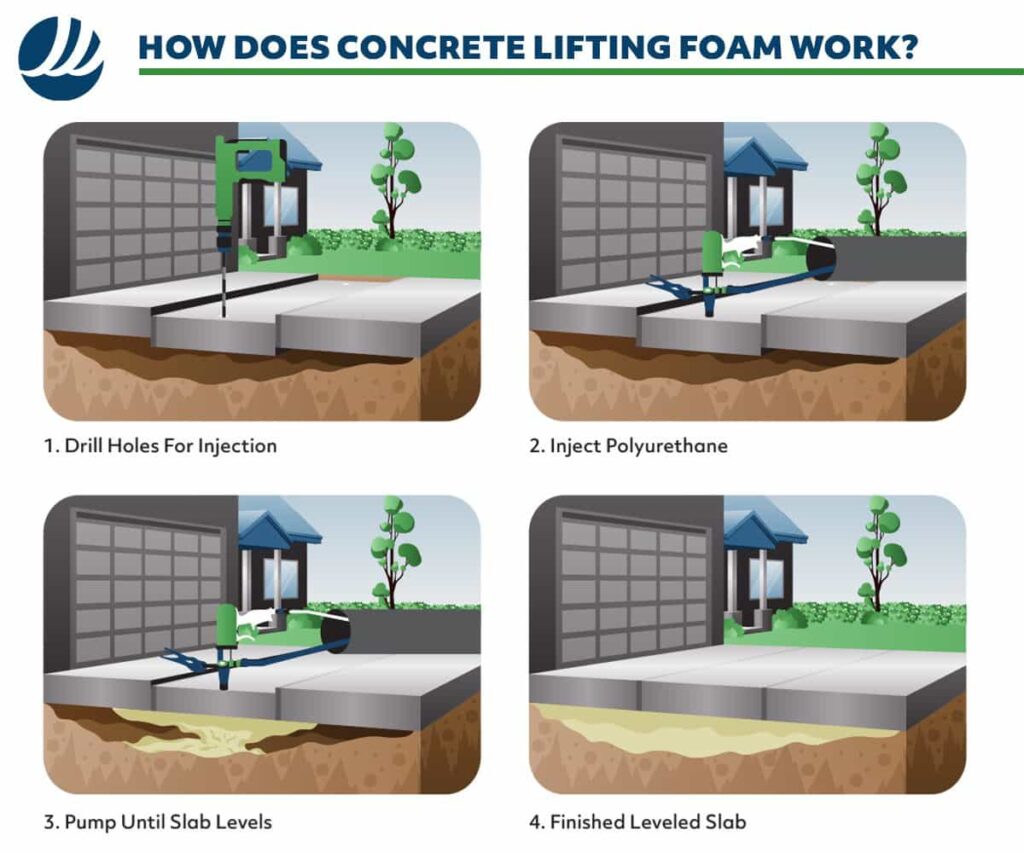

Polyurethane Foam Injection(the most common technique used today to raise a slab)

Today, raising a concrete slab with foam – a type of strong, polyurethane material – is the most popular repair method for fixing an uneven slab. Other names for this technique include poly foam, foam jacking, polyjacking, and foam lifting.

- Step one: Dime-sized holes are drilled into the uneven slab.

- Step two: The concrete lifting foam is injected under the concrete. It immediately expands, filling the voids and lifting the slab.

- Step three: The holes are patched using a compound that matches the concrete.

Why Raising A Slab With Foam Is Better Than Mudjacking

We believe raising a slab with foam is better than mudjacking for various reasons, including:

- Concrete lifting foam is synthetic and won’t erode away over time. Of course, there’s always a chance the soil under the foam will erode if there’s poor drainage under the slab. However, unlike the mudjacking slurry, the foam itself will not disintegrate if it comes into contact with water.

- Concrete lifting foam is lightweight. One problem with mudjacking is the weight of the cement slurry. If the slab became uneven because the soil under it was weak, adding more weight to the soil could cause the slab to sink even more.

- Raising a concrete slab with foam is a quicker repair. Most jobs can be completed in just a few hours, and you can start using the slab again 15 minutes after the repair is complete.

- Mudjacking can get messy. Mudjacking requires heavy equipment and tends to create a mess, which means clean-up.

- Raising a concrete slab with foam only requires dime-sized holes. The holes necessary for mudjacking are usually 2-3 inches in width. Therefore, they’re more visible when patched.

For more information about raising a concrete slab with foam, see Common Questions About Concrete Lifting Foam.

Raising Concrete With Foam Is Less Expensive Than Replacing The Slab

Digging up the uneven slab and pouring new concrete is expensive and time-consuming. Freshly poured concrete takes time to dry and harden. While that’s happening, you won’t be able to use the slab. Raising a concrete slab with foam usually takes no more than a few hours. As soon as the repair is complete, you can start using the slab again.

Of course, sometimes, a concrete slab is too damaged to raise it using foam. In these cases, replacing it is the only solution.

The Cost Of Raising A Slab With Foam

The cost of raising a concrete slab with foam is more than mudjacking but less than digging up the old slab and pouring a new one. Of course, the cost depends on where you live and the size of the affected slab (which determines how much foam is required). Contact a foundation repair contractor that does concrete leveling and ask for an inspection and estimate.

If you’re in our Kansas City, MO service area and need a concrete slab raised, contact KC Waterproofing and Foundation Repair today for an inspection and repair estimate.